Infrared measurement response time

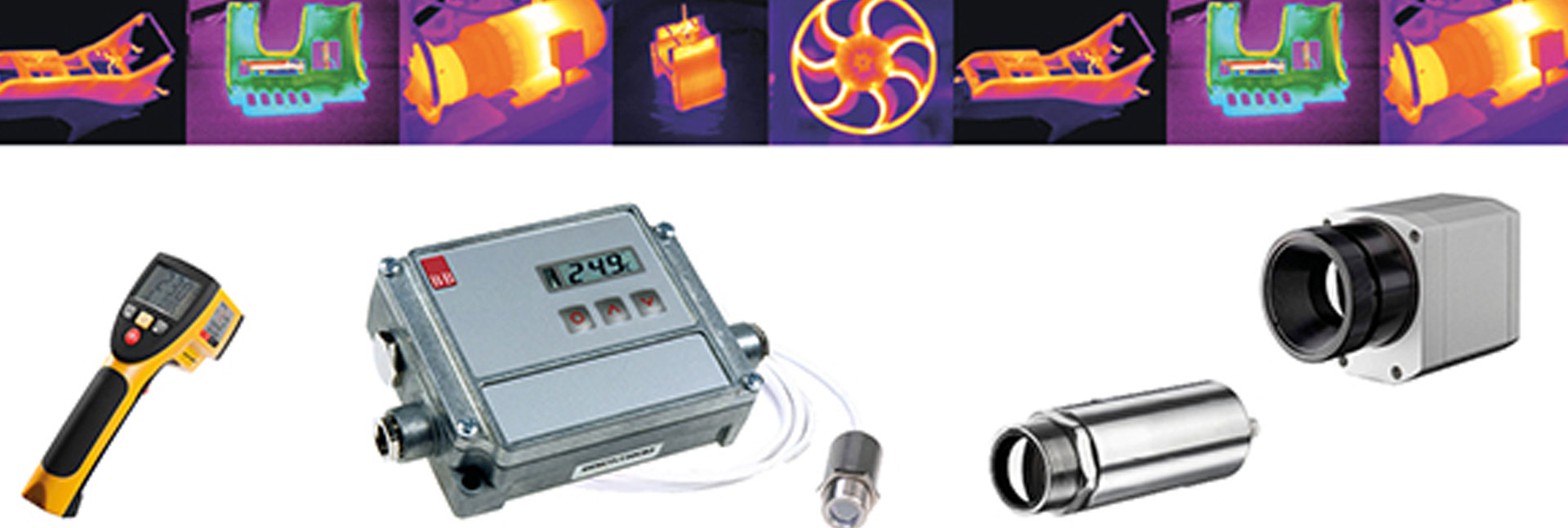

In addition to invasive and non-invasive temperature sensors, B+B also offers contactless temperature measurement. With the help of our infrared products it is possible to measure temperatures over distances. This technology is particularly suitable for moving measurement objects and applications where a very fast reaction or response time is required.

If you know where the critical area or the area to be measured is located in your application, a spot-measuring infrared thermometer should be used. The size of the measuring object determines which optics are selected for the measuring device. This enables you to monitor the temperature precisely and, if necessary, optimize the process – before quality problems occur. One area of application for this is, for example, control cabinet construction.

Our infrared thermometers “Made in Germany” are suitable for these stationary applications. Exact measuring results, measuring spot markings and high-quality accessories characterize our DM series. With the pyrometers the measurement of most different materials is possible. The spectral ranges extend from plastics to a wide variety of metals. Among them are applications such as the temperature measurement of granules in injection molding, the detection of temperature in the production of flat films and sheet extrusion, as well as in induction hardening, deep drawing, metal casting or die forging. In addition, our infrared products are also used in the glass industry and in all areas where quality needs to be monitored, processes optimized and research / development drive new product lines. Due to the modular design and the enormous product range it is possible to detect almost any material with the pyrometers and to measure the surface temperature. For the optimal design you are welcome to contact us.

In case there is not only one critical area or this area cannot be localized exactly, the use of infrared cameras is more reasonable and effective. This is the case, for example, in PET or glass bottle production. Often critical areas are localized with the camera via thermal imaging and then permanently monitored with the help of one or more stationary infrared thermometers.

Depending on the application, you can get small infrared and thermal imaging cameras with large technology. The thermal imaging cameras provide you with exact temperature values in real time and are used in a wide range of industries, such as medical technology, the automotive industry and mechanical engineering. All thermal imaging cameras can be connected to your computer via USB 2.0. This gives you high-resolution images to analyze area measurements and save temperature curves. The cameras are available in different versions with selectable lenses, specially tailored to different requirements.

Even in medical technology and in times of the coronavirus our infrared products help to measure body temperatures and surfaces. In order to detect larger crowds, the infrared cameras are needed, for random temperature measurements, our handheld measuring devices are particularly suitable.

Other interesting topics

Newsletter registration

Stay up to date with us free of charge. Don't miss any more news, novelties or information with our free newsletter!