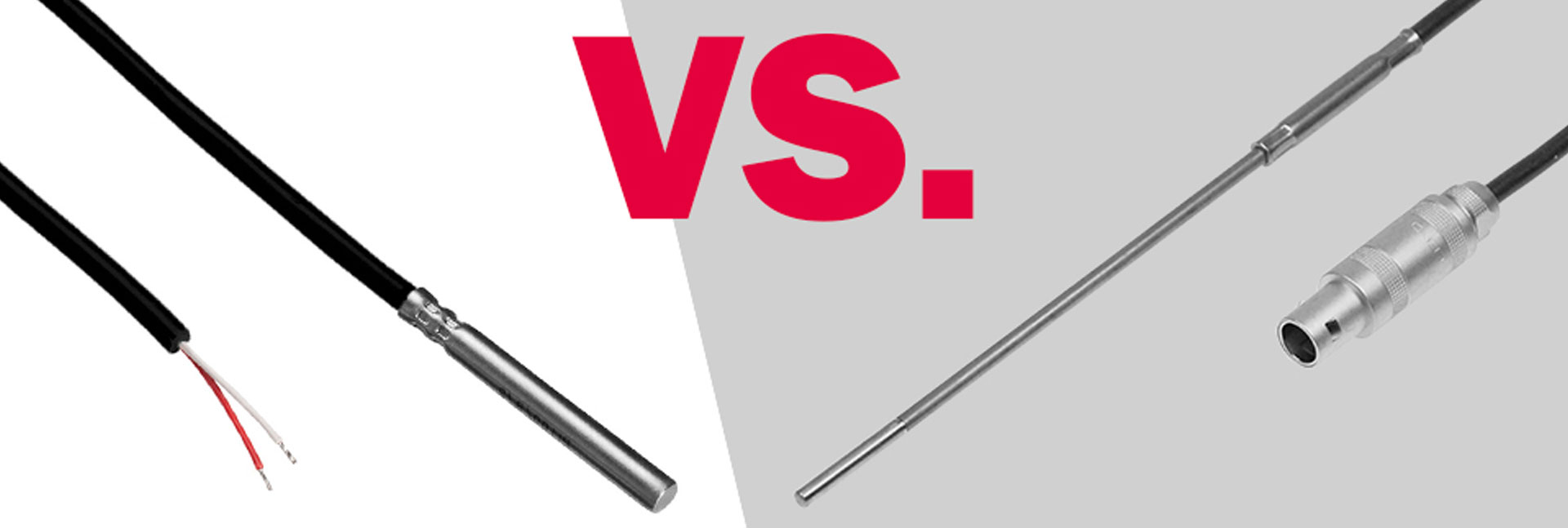

Cable probe vs. resistance thermometer

There is more than one way to measure the temperature in an application. The simplest option is certainly the cable sensor. But the higher the demands on the sensor, the faster the simple cable sensor reaches its limits. Operating temperature, installation situation, flexibility and reproducibility are just some of the influencing factors. For this reason, cable sensors and sheath resistance thermometers (also called resistance thermometers or sheath sensors) are compared and areas of application are shown.

The classic cable sensor

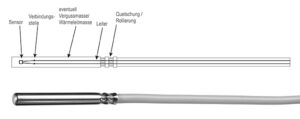

Simply constructed cable temperature sensors without the insertion of potting compound and thermal paste as well as certain insulation elements are quite easy to manufacture. They consist of a cable, to the end of which a sensor element (e.g. platinum sensor) is connected. The entire measuring insert (this is the name given to the sensor including insulation and possibly heat shrink tubing on the cable) is placed in a protective sleeve which protects it from environmental influences. With the help of the potting compounds already mentioned, a high IP protection class (up to IP68) can also be achieved for these sensors. Fast response times are also achieved through the use of thermal paste. Fixation by crimping or rolling ensures a secure connection between sleeve and cable. Depending on raw material prices and the design of the measuring insert, the classic cable probe can be a very cost-effective option for temperature measurement. A low number of parts and work steps also ensures a low price in production.

Depending on the requirements, however, even this simple design of temperature measurement reaches its limits. Although the cable probes can be potted waterproof up to a maximum continuous temperature of approx. 350 °C, there is still the possibility that water vapor can get inside the probe. Particularly when fiber optic cables are used at high ambient temperatures (>260 °C), moisture can penetrate the measuring insert and impair its function. Reproducibility is also only possible to a limited extent. The position of the sensor varies slightly from probe to probe, which can lead to slight deviations in the measured values. Last but not least, the installation situation often requires a structural adjustment of the temperature probe. The protective sleeve of cable probes is rigid and therefore offers few options for flexibility. Especially sensors with a thread, so-called screw-in sensors, require more space. However, depending on the installation space, this may not be available.

In such cases, a sheath resistance thermometer can be used.

The mineral insulated resistance thermometer

Similar to the structure of a sheath thermocouple, the sheath resistance thermometer consists of two conductors, which, however, are not made of thermocouple material but of copper. These are enclosed by magnesium oxide and a stainless steel sheath (e.g. Inconel 600). In measurement technology, this is referred to as a sheathed slotted cable. It is shortened to the desired length and the sensor element (e.g. Pt1000) is welded to the exposed copper wires. With this procedure it is possible to place the sensor elements always in the same position, even if 2 sensor elements are installed in one probe, which must be in the same height and radial position. Deviations when changing a probe are thus also excluded.

Another stainless steel sleeve encloses the sensor elements and is welded to the end of the sheathed slotted line. Now the sensor elements are embedded in firmly compacted magnesium oxide. At the end, the probe is sealed with a pastille. Thanks to the magnesium oxide, the sensors are encapsulated in a vapor-tight manner and, due to their design, can withstand high pressures and temperatures of up to 600 °C without any problems. The robust design makes the probes shock-resistant and durable. Another major advantage: The sheathed slotted cable can be bent and thus individually adapted to the application and design.

All these advantages and properties mean that a sheathed resistance thermometer requires considerably more and higher-quality basic materials. The manufacturing processes are also more complex, so the price is higher than for a simple cable probe. Compared to a high quality cable probe (with R fiber optic cable), there is almost no difference in price.

So the selection of the right probe depends on various factors in the application and the requirements for the probe or the accuracy of the measured value. We are happy to assist you with advice and assistance in the design of the appropriate sensor.

| Cable probe | Mineral insulated resistance thermometer | |

| Advantages |

|

|

| Disadvantages |

|

|

Other interesting topics

Newsletter registration

Stay up to date with us free of charge. Don't miss any more news, novelties or information with our free newsletter!